One of the most critical aspects of operating a mini batch plant is achieving the correct mixing ratios for short-load concrete mixes. Proper mixing ratios ensure consistent quality, strength, and durability in every batch.

What is a Concrete Mix Ratio?

Concrete is made from combining raw materials together in different amounts, referred to as a ratio, to create a desired outcome. Sometimes that outcome is a specific strength, durability or workability requirement for a project. Understanding your project needs will help you determine the precise mixing ratio needed when creating a batch of concrete. Much like baking a cake, the core ingredients in a concrete recipe are the same, but the amounts of each can change your recipe drastically. So, what are those core ingredients?

- Cement

- Aggregates like sand, gravel, crushed stone, recycled concrete or asphalt, or a manufactured substance like slag or clay.

- Water

Common Concrete Mixing Ratios

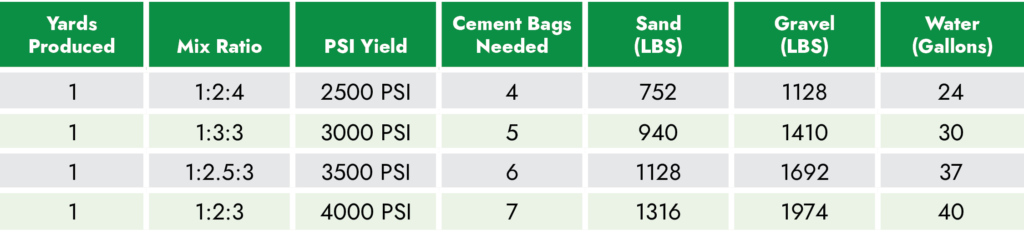

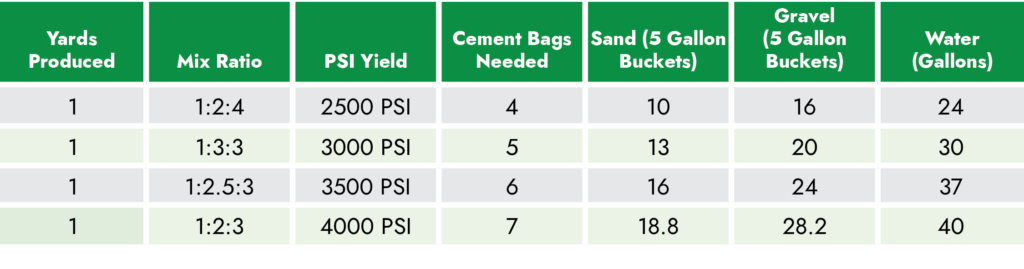

Mini batch plant operators frequently use several standard concrete mixing ratios depending on the application. The most common ratios include:

1:3:3 (Cement: Sand: Gravel) – This ratio consists of one part cement, two parts sand, and four parts gravel. It is widely regarded as one of the best mixing ratios for producing a 3000 PSI concrete mix. This mix can withstand heavy loads and structural stresses and is ideal for footings, concrete patios, and foundation walls.

1:2:4 (Cement: Sand: Gravel) – Also known as M15, this ratio typically yields a concrete mix with a compressive strength of around 2900 PSI. It is commonly used for residential and light commercial construction, such as foundations and floor slabs.

1:2:3 (Cement: Sand: Gravel) – This high-strength ratio produces concrete with a compressive strength of approximately 4000-4500 PSI after a full 28-day curing period. It’s one of the most popular mix ratios in construction for a reason and covers a lot of bases!

Achieving Accurate Mixing Ratios

To ensure consistent results, accurate measurement of each aggregate is essential. Ready Mixer wheel loaders come equipped with weight scales allowing operators to precisely measure materials before loading the hopper. For customers using skid steers, our sales team can recommend trusted suppliers of weight scale attachments to retrofit an existing machine.

By incorporating weight scales directly into the loading process, operators can maintain high hourly production rates without sacrificing mix accuracy.

Water Measurement and Cleanout Options

Accurate water content is critical for achieving the desired mixing ratios and ensuring consistent concrete strength across all batches. “Water is the catalyst for the cement’s chemical reaction,” says All Mix Concrete in their article explaining concrete mixing ratios. “The right amount of water is crucial to achieve the desired workability and strength.” To help create the perfect mixture with just the right amount of water, Ready Mixer offers optional water attachments that can be used for both cleaning and precise water measurement.

Selecting the right concrete mixing ratios is vital for producing high-quality concrete in mini batch plant operations. Whether you’re mixing for footings, slabs, or small residential structures, having the proper equipment and processes in place will help you deliver consistent, durable concrete to your customers.

Contact us today to learn more about our mini batch plant solutions and how our weight scales and water attachments can streamline your production process.