For many short-load concrete plant operators, using bagged cement has been the standard approach for years. It’s accessible, familiar, and doesn’t require specialized storage. But while bagged cement might seem convenient, it’s far from cost-effective—especially when you scale operations.

At Ready Mixer, we work with concrete professionals who understand the value of operating lean. One of the most overlooked ways to cut costs and boost efficiency? Investing in a cement silo and switching to bulk delivery. That’s why we put our nose to the ground, collected data and crunched the numbers to see what professionals like you are paying for bulk vs. bagged cement and ways to bring those costs down across the board.

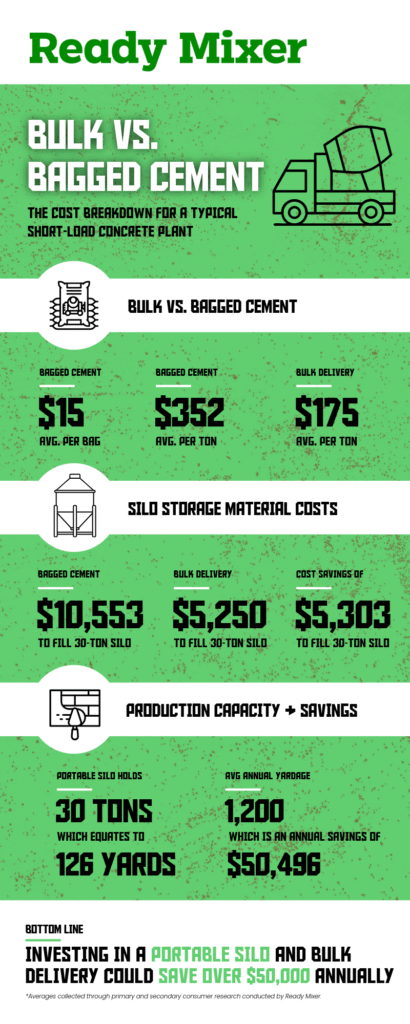

Bulk vs. Bagged Cement: The Real Cost

On average, a 94 lb. bag of cement costs around $15. Multiply that out and you’re paying approximately $352 per ton. Now compare that to bulk cement delivery, which averages around $175 per ton. That’s a 50% savings every time you fill your cement silo.

Silo Fill Costs: The Savings Are Clear

A standard portable cement silo holds 30 tons. Given the average costs calculated above, here’s what it costs to fill a silo with each option:

Bagged Cement: $10,553

Bulk Cement: $5,250

Savings Per Fill: $5,303

Even if you’re operating on a smaller scale, those savings stack up quickly. Most short-load plants go through around 1,200 yards of concrete per year, requiring about 9–10 full cement silo fills.

That translates into a total annual savings of $50,000 or more just by switching to bulk cement and silo storage.

Why a Cement Silo is a Smart Investment

The idea of adding a cement silo might seem like a big capital expense—but it’s an investment that pays for itself in less than a year for most operators.

Beyond cost savings, a cement silo also improves operational efficiency. It reduces manual labor, minimizes downtime from bag handling, and improves site cleanliness. Plus, bulk delivery is far more consistent and scalable as your business grows.

Bottom Line

If you’re still operating your plant with bagged cement, you’re not just spending more—you’re working harder to produce less.

By upgrading to a cement silo and switching to bulk delivery, short-load operators can significantly reduce costs, increase efficiency, and boost their bottom line.

📊 Check out the infographic above for a full cost breakdown.

💡 Interested in adding a portable cement silo to your operation? Let’s talk about how Ready Mixer can help you save time, money, and hassle—starting today.